How to Calculate the Distance between the Avoidance Angle and the Target in a Mold Base Model Framework

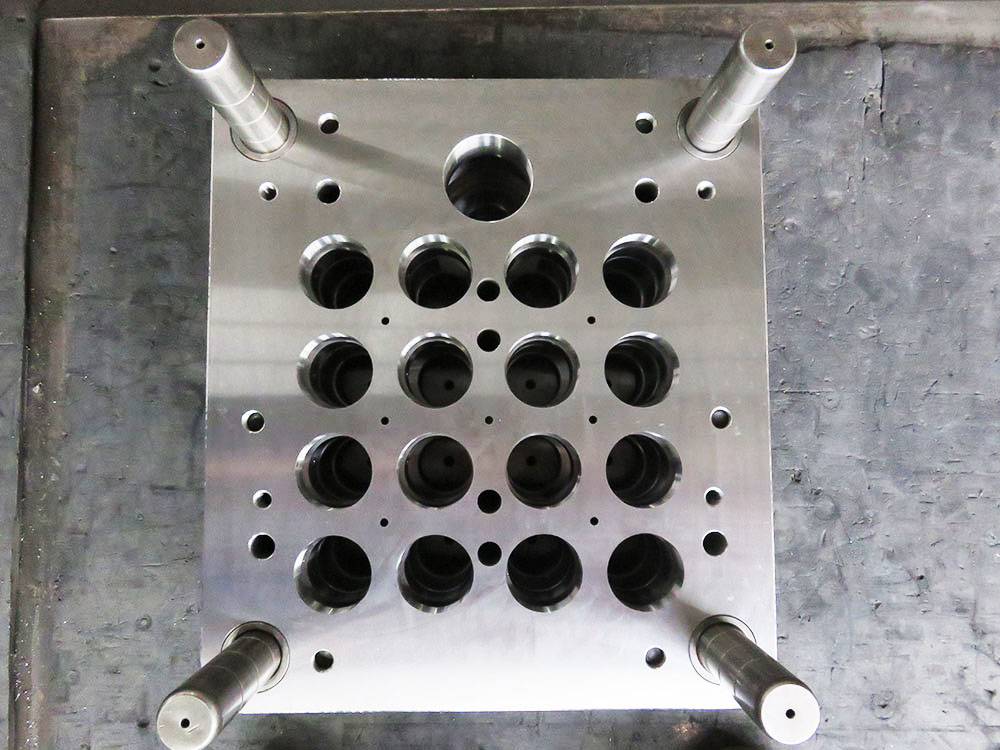

In the mold base industry, it is crucial to calculate the distance between the avoidance angle and the target accurately. This calculation helps in designing and manufacturing high-quality molds that meet the specifications of the desired product. In this article, we will discuss different methods to calculate this distance within a model framework.

Method 1: Using Geometrical Calculation

The first method to calculate the distance between the avoidance angle and the target is by employing geometrical calculation techniques. This approach involves analyzing the model framework and measuring the relative positions of the avoidance angle and the target.

Step 1: Identify the avoidance angle and the target points in the model framework. This can be done by thoroughly examining the mold design and understanding the specific parts or features that need to be avoided during the molding process.

Step 2: Measure the distance between these two points using the appropriate measuring tools. Ensure that the measurement is in the same unit as specified in the model framework (such as inches or millimeters).

Step 3: Calculate the distance by subtracting the coordinates of the avoidance angle from the coordinates of the target point. Ensure to consider both the X-axis and Y-axis distances separately.

Step 4: Apply pythagorean theorem to find the final distance between the avoidance angle and the target point. Use the formula: distance = sqrt((x2-x1)^2 + (y2-y1)^2), where (x1, y1) are the coordinates of the avoidance angle and (x2, y2) are the coordinates of the target point.

Method 2: Utilizing CAD Software

The second method involves using Computer-Aided Design (CAD) software to calculate the distance between the avoidance angle and the target. This method is effective when working with complex mold designs or when a high level of accuracy is required.

Step 1: Import the model framework into the CAD software. Ensure that the avoidance angle and the target points are clearly defined and identifiable.

Step 2: Use the measurement tools provided by the CAD software to measure the distance between the avoidance angle and the target. Most CAD software allows users to measure the distances directly on the model framework.

Step 3: Record the measured distance and apply any additional calculations or formulas required based on the specific mold design guidelines or requirements.

Method 3: Simulation Software

The third method uses simulation software specifically designed for the mold base industry. These software solutions offer advanced features for analyzing and calculating various aspects of mold design, including the distance between the avoidance angle and the target.

Step 1: Import the model framework into the simulation software. Ensure that the avoidance angle and the target points are properly defined within the software.

Step 2: Set up the simulation parameters according to the specific mold design requirements. This may include specifying the mold material, mold temperature, injection molding process parameters, etc.

Step 3: Run the simulation and observe the results. Most simulation software provides visual outputs that display the distance between the avoidance angle and the target.

Step 4: Analyze the simulation results and extract the distance measurement between the avoidance angle and the target. Make any necessary adjustments or modifications to the mold design based on the obtained data.

Conclusion

Calculating the distance between the avoidance angle and the target in a mold base model framework is crucial for ensuring the accuracy and efficiency of the mold design and manufacturing process. By using appropriate geometrical calculations, CAD software, or simulation software, mold base professionals can determine the required distance accurately. This knowledge enables them to create molds that avoid interference and produce flawless products.