How to Achieve Precision Processing of Modular Frame Manufacturing?

The modular frame manufacturing industry plays a crucial role in various sectors, providing the necessary support structures for a wide range of applications. Achieving precision processing in this industry is essential as it ensures the overall quality, functionality, and durability of the modular frames. In this article, we will explore some of the key factors and techniques involved in achieving precision processing in modular frame manufacturing.

1. Design and Engineering

Before starting the manufacturing process, it is essential to have a well-defined design and engineering phase. This phase involves conceptualizing the modular frames, creating 3D models, and conducting feasibility studies. It is crucial to consider factors such as load-bearing capacity, material selection, assembly requirements, and any specific industry standards or regulations that need to be followed.

2. Material Selection

The choice of materials used in modular frame manufacturing significantly impacts the precision processing. Depending on the application and requirements, materials such as aluminum, steel, or composite materials may be selected. It is important to consider factors such as strength, weight, corrosion resistance, thermal stability, and cost-effectiveness when selecting the materials. Careful material selection helps in achieving the desired precision in the manufacturing process.

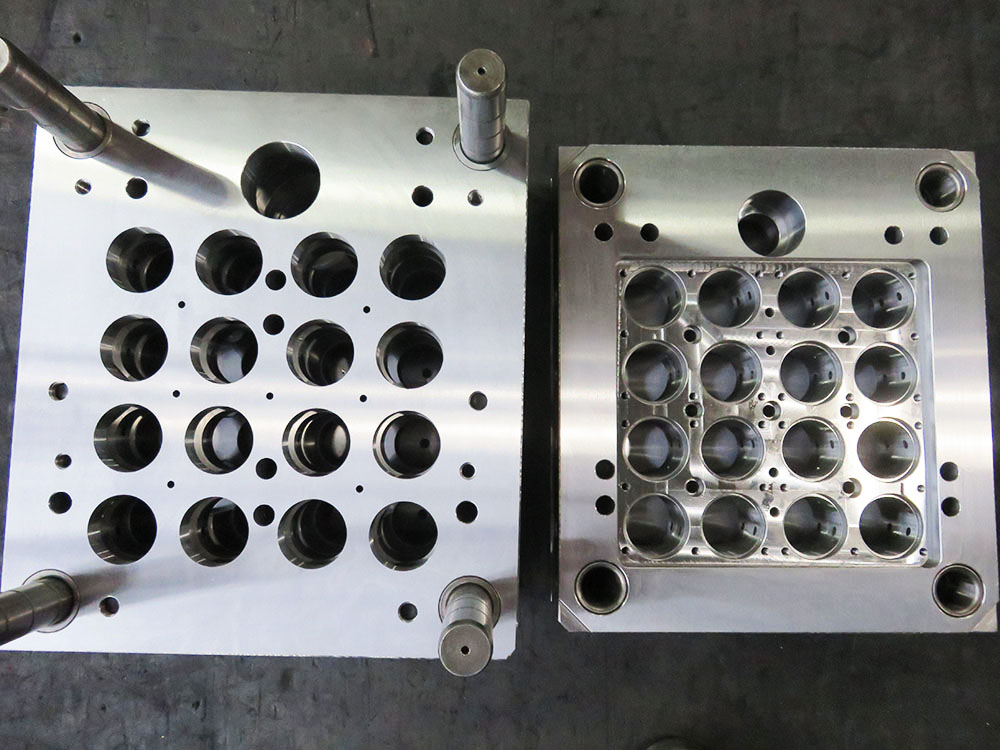

3. Advanced Machining Techniques

Precision processing of modular frames involves the use of advanced machining techniques. CNC (Computer Numerical Control) machines play a crucial role in achieving precision and accuracy in the manufacturing process. These machines automate the machining operations and ensure consistent results. High-speed milling, drilling, and turning techniques, combined with computer-aided design (CAD) and computer-aided manufacturing (CAM) software, enable precise shaping and cutting of the modular frame components.

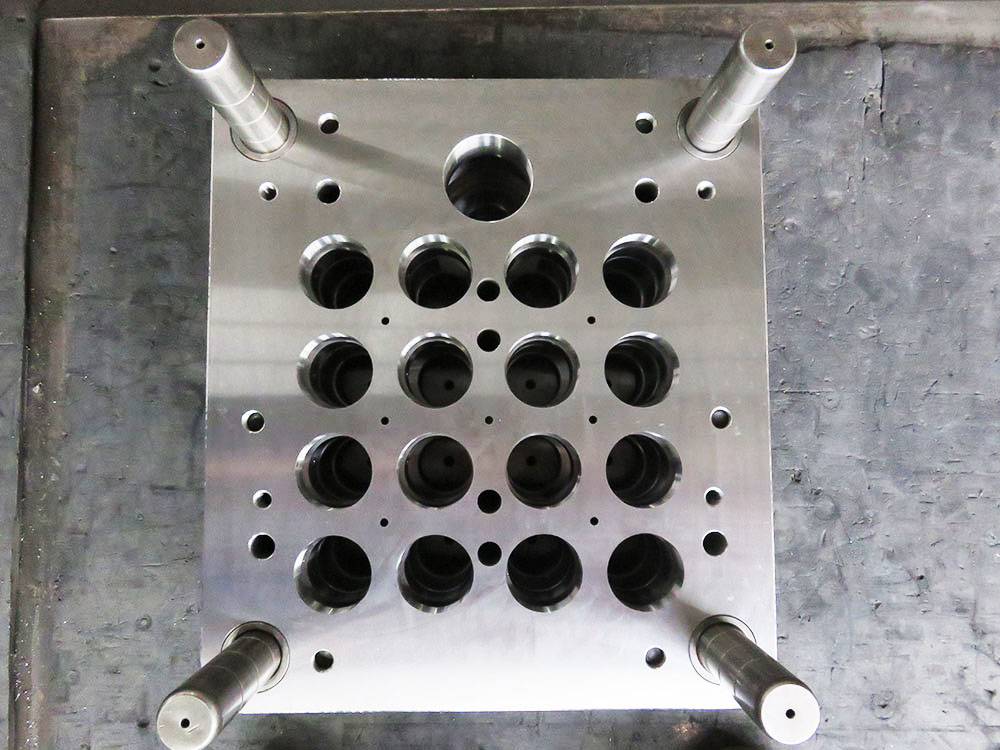

4. Quality Control and Inspection

Implementing a robust quality control and inspection process is vital for achieving precision processing in modular frame manufacturing. This includes conducting regular checks and inspections at various stages of the manufacturing process, such as material receiving, machining, assembly, and finishing. Advanced measurement tools, including Coordinate Measuring Machines (CMMs), laser scanners, and optical comparators, help ensure that the dimensions and tolerances of the modular frame components are within the desired range.

5. Assembly and Integration

The precision processing of modular frame manufacturing extends to the assembly and integration of the components. A well-designed assembly process ensures that each component fits accurately, resulting in a sturdy and reliable modular frame. The use of precision jigs, fixtures, and alignment tools helps in achieving precise positioning and proper alignment of components during the assembly process. Additionally, implementing stringent quality checks during assembly ensures that any potential defects or deviations are identified and rectified before the final product is delivered.

6. Continuous Improvement

Achieving precision processing in modular frame manufacturing is an ongoing process that requires a mindset of continuous improvement. Regular feedback from customers, evaluation of manufacturing processes, and incorporating new technologies and techniques are essential for enhancing precision and efficiency. Continuous improvement initiatives, such as Six Sigma or Lean Manufacturing, help in identifying and eliminating waste, reducing errors, and improving overall quality and precision.

In conclusion, achieving precision processing in modular frame manufacturing requires a combination of factors such as design and engineering, material selection, advanced machining techniques, quality control and inspection, assembly and integration, and a focus on continuous improvement. By addressing these key areas, manufacturers can ensure the production of high-quality, precise, and reliable modular frames that meet the diverse needs of various industries.