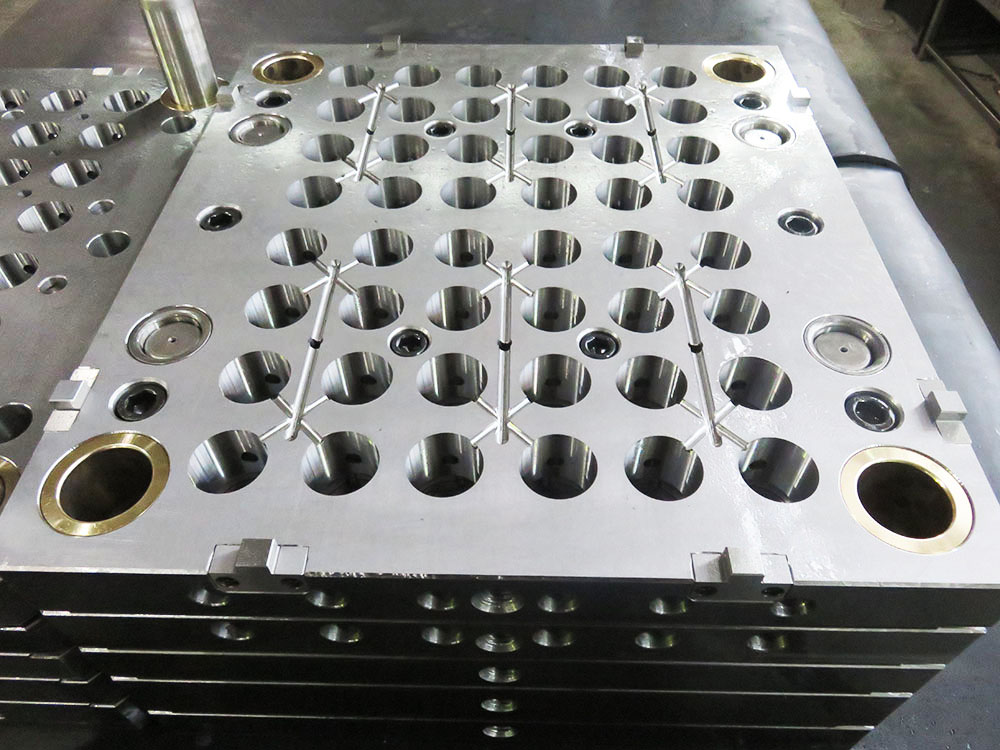

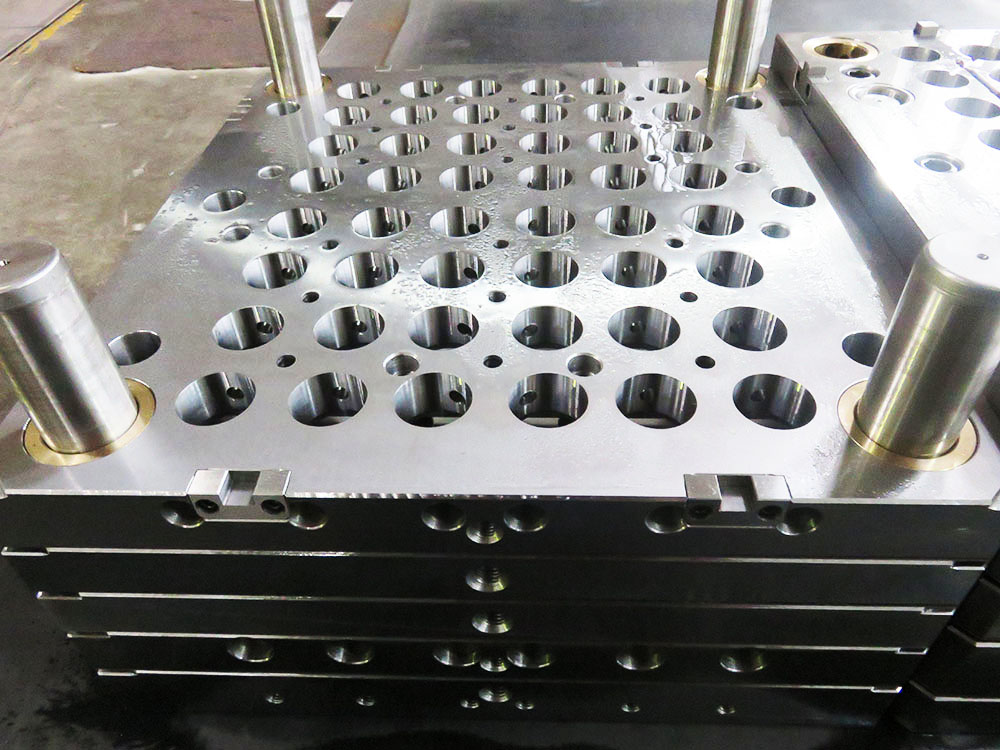

Mold bases and mold bases can be used in industries such as automobiles, household appliances, medical equipment, precision electronics, mobile communications, instrumentation, and building blocks and toys. The accuracy requirements for products are getting higher and higher. Therefore, the accuracy of mold manufacturing and mold base production is very important. The requirements are getting higher and higher, so precision mold bases are born. The main characteristics of precision mold bases are high dimensional accuracy, small tolerances, and high matching accuracy.

Mold bases and mold bases can be used in industries such as automobiles, household appliances, medical equipment, precision electronics, mobile communications, instrumentation, and building blocks and toys. The accuracy requirements for products are getting higher and higher. Therefore, the accuracy of mold manufacturing and mold base production is very important. The requirements are getting higher and higher, so precision mold bases are born. The main characteristics of precision mold bases are high dimensional accuracy, small tolerances, and high matching accuracy.

It depends on the complexity of the processing project. Please consult customer service staff for details.

1. In addition to standard mold bases, can mold base products be used for other processing projects?

● The following additional processing items can be performed on mold base products: changing steel types for AB plates and push plates, rough (finish) frame processing, fine frame chamfering, round frames, back stitching through push plates, limit nails, and guide column inversion. , standard needle, board edge (EGP), standard code die pit, fine surface code die pit, top pin hole, side lock (SIDELOCK), top lock (TOPLOCK), slant guide position assistant (TAPERBLOCK), nozzle hole, Code mold iron (lock module).

● If the above processing items cannot meet your needs, please contact our sales window directly.

1. 24-hour professional after-sales service team

2. Solve problems as soon as possible and then implement responsibilities. Don’t waste time on determining responsibilities.

3. After-sales visits from time to time to understand the usage situation at any time