Definition of Size for Combining a Truss Clamp with a Side Lock

In the mold base industry, the combination of a truss clamp with a side lock is a critical aspect of design and manufacturing. It involves determining the appropriate size for this combination, which plays a crucial role in ensuring the stability and functionality of the mold base. This article will delve into the definition of size for combining a truss clamp with a side lock, focusing on industry standards and best practices.

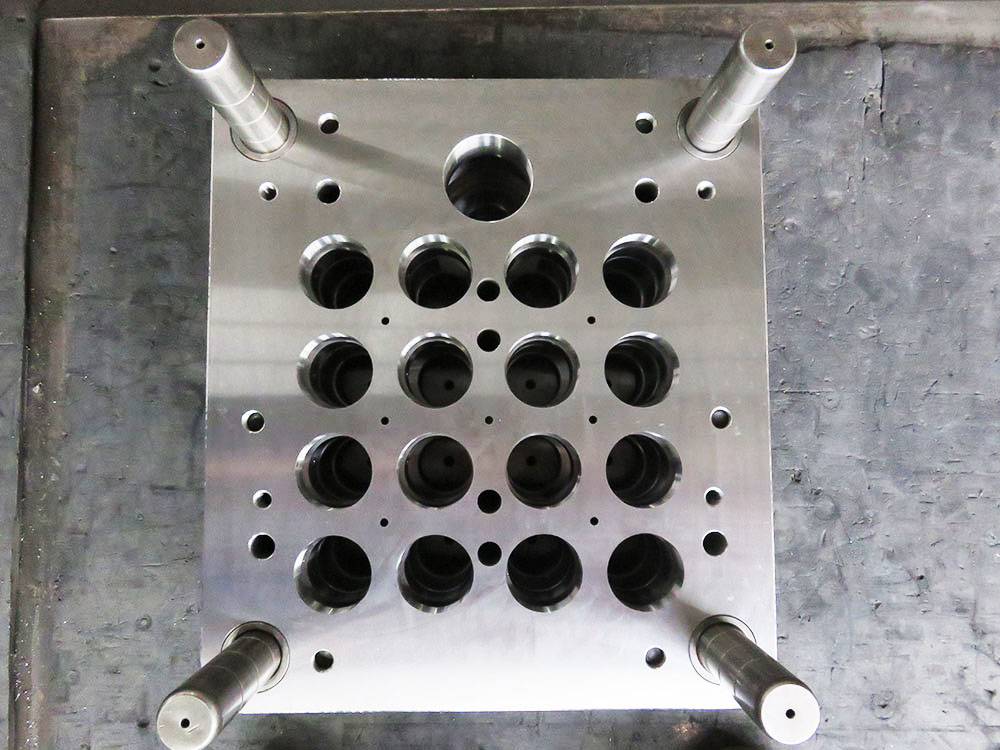

First and foremost, it is essential to understand the purpose of combining a truss clamp with a side lock. This combination is typically used to secure and lock the mold insert or core in place within the mold base. The truss clamp provides a strong and stable connection, while the side lock further enhances the locking mechanism to prevent any movement during the injection molding process. The size of this combination is crucial as it directly impacts the overall integrity and performance of the mold base.

When determining the size for combining a truss clamp with a side lock, several factors need to be considered. These factors include the size and weight of the mold insert or core, the amount of force exerted during the molding process, and any potential design or dimensional constraints. It is crucial to ensure that the selected size can withstand the pressures and forces applied during the injection molding process without compromising the stability of the mold base.

Industry standards play a vital role in defining the appropriate size for combining a truss clamp with a side lock. The American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) provide guidelines and specifications that manufacturers and designers should adhere to. These standards define the dimensions, tolerances, and load-bearing capacities for various sizes of truss clamps and side locks, ensuring consistency and compatibility across different mold base designs.

Additionally, it is crucial to consider the material properties when determining the size for combining a truss clamp with a side lock. The material used for these components should possess sufficient strength, durability, and resistance against wear and tear. Common materials used in the mold base industry include high-strength steels, such as P20 and H13, which exhibit excellent mechanical properties and can withstand the forces encountered during injection molding.

Another consideration when defining the size for combining a truss clamp with a side lock is the ease of installation and maintenance. It is essential to select a size that allows for easy and efficient assembly, disassembly, and adjustment of the mold base components. This consideration not only saves time and resources during the manufacturing process but also facilitates any necessary maintenance or repairs that may be required during the lifespan of the mold base.

In conclusion, the size for combining a truss clamp with a side lock in the mold base industry is a crucial aspect of design and manufacturing. It directly affects the stability, functionality, and overall performance of the mold base. By considering factors such as mold insert size, force exertion, industry standards, material properties, and ease of installation, manufacturers and designers can ensure that the selected size is appropriate for the intended application. Adhering to these best practices and industry standards will lead to the production of high-quality mold bases that meet the demanding requirements of the injection molding process.