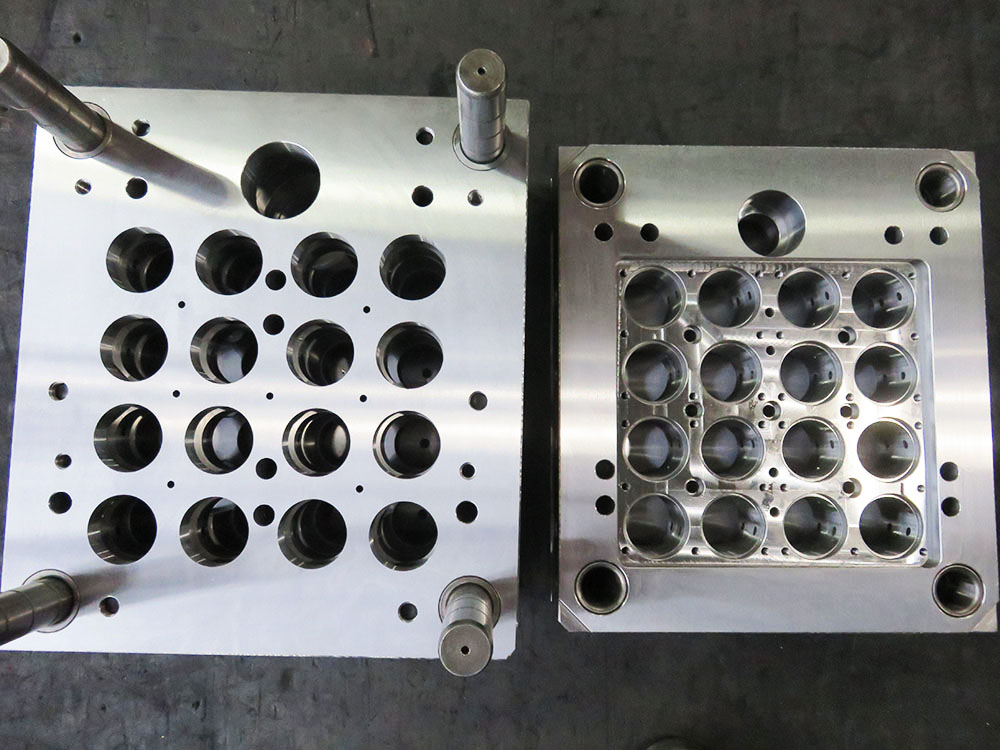

How to Determine the Solidified Volume of Injection Molding Inserts in the Mold Frame

Injection molding is a widely used manufacturing process in the mold base industry. It involves the creation of solid parts by injecting molten material into a mold cavity, which then cools and solidifies. Determining the solidified volume of injection molding inserts in the mold frame is crucial for ensuring the accuracy and success of the molding process. In this article, we will explore the methods and factors involved in determining the solidified volume.

1. Mold Design Considerations

The design of the mold plays a significant role in determining the solidified volume of injection molding inserts. The size, shape, and complexity of the mold cavity, as well as the position and number of inserts, influence the final volume. Careful consideration should be given to factors such as shrinkage, parting line location, and venting to ensure consistent and accurate volume calculations.

2. Material Selection

The choice of material for the injection molding inserts also affects the solidified volume. Different materials have varying shrinkage rates during the cooling and solidification process. It is essential to have a thorough understanding of the material properties and to account for any potential shrinkage when calculating the solidified volume.

3. Calculation Methods

There are several methods available for determining the solidified volume of injection molding inserts in the mold frame. These methods include:

- Mold Flow Analysis:

Mold flow analysis software provides a comprehensive understanding of the injection molding process, including the solidified volume. By simulating the mold filling and solidification process, the software can accurately predict the final volume and identify any potential issues or defects.

- Cavity Pressure Monitoring:

By monitoring the cavity pressure during the injection molding process, it is possible to estimate the solidified volume. Certain pressure-volume relationships can be established based on empirical data, allowing for a reliable estimation of the final volume.

- Calculation Formulas:

There are various mathematical formulas available for calculating the solidified volume of injection molding inserts. These formulas consider factors such as the mold cavity size, shrinkage rate, and material properties to determine the final volume.

4. Experimental Validation

To ensure the accuracy of the calculated solidified volume, experimental validation is recommended. This involves conducting test injections using the chosen mold design and material to compare the predicted volume with the actual volume obtained. Any discrepancies can then be analyzed and adjustments made to improve the accuracy of future volume calculations.

Conclusion

The determination of the solidified volume of injection molding inserts in the mold frame is a critical aspect of the mold base industry. Proper mold design, material selection, and calculation methods are essential for achieving accurate volume predictions. Experimental validation further enhances the reliability and precision of the results. By carefully considering these factors and techniques, mold makers can ensure the success of the injection molding process and deliver high-quality molded parts.