What to expect during scaffolding acceptance in the Mold Base industry?

Acceptance of scaffolding is a critical step in ensuring safety and efficiency in the Mold Base industry. Scaffolding provides a temporary structure to support workers and materials during construction, repair, or maintenance of mold bases. It is crucial to have a clear understanding of what to expect during scaffolding acceptance to ensure a smooth and secure working environment. This article will outline the key aspects of scaffolding acceptance in the Mold Base industry.

1. Compliance with regulations and standards

During scaffolding acceptance, it is essential to verify that the scaffold design and installation comply with relevant regulations and industry standards. This includes ensuring adherence to safety codes, such as OSHA guidelines, and proper engineering calculations to support the intended load. Inspections should confirm that scaffolding is appropriately erected, braced, and secured according to specifications.

2. Structural integrity and stability

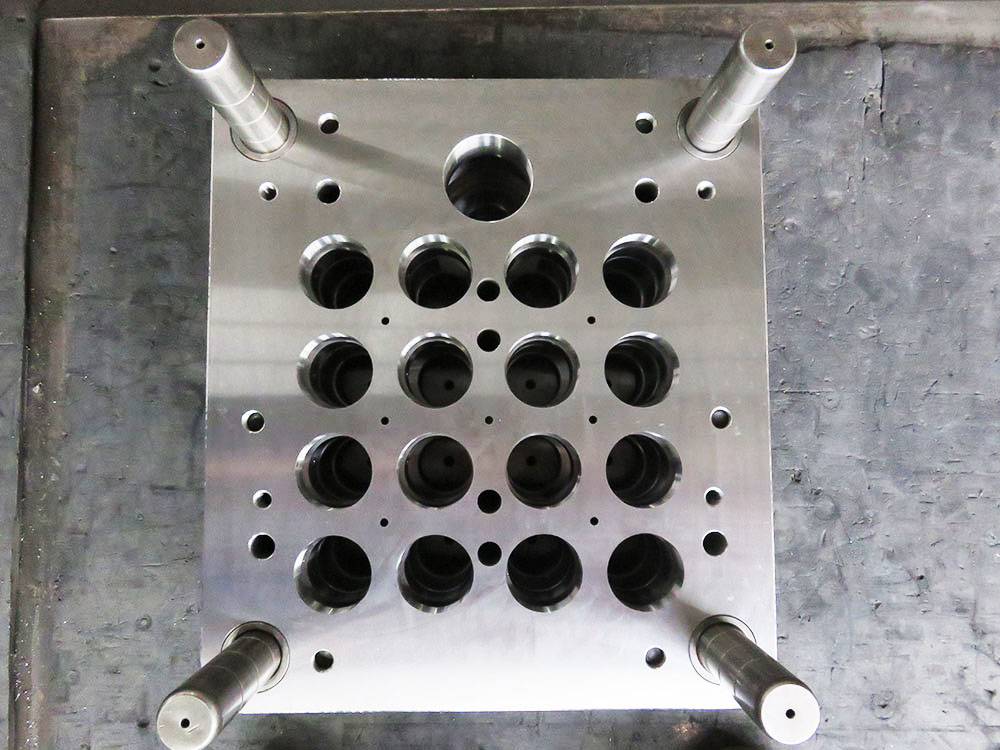

Another critical aspect of scaffolding acceptance is assessing the structural integrity and stability of the scaffold system. This involves examining the materials used for scaffold construction, such as steel or aluminum, and ensuring their quality and suitability for the specific job requirements. Additionally, inspections should verify that the scaffold is stable and level, with proper foundation support and bracing to prevent collapse or movement during use.

3. Adequate access and platform safety

Accessible and safe platforms are vital in the Mold Base industry to facilitate efficient work and protect the well-being of workers. During scaffolding acceptance, inspectors will check that there is suitable access to the work area, such as ladders or stairs, and that these access points are secure and properly attached. They will also assess the platform's condition, dimensions, and guardrails to ensure they meet safety standards, reducing the risk of falls or accidents.

4. Load-bearing capacity

Load-bearing capacity is a crucial factor in scaffolding acceptance, as it determines the maximum weight the scaffold can safely support. Inspections should verify that the scaffold's load-bearing capacity aligns with the intended use and the weight it will bear, including workers, materials, and equipment. This involves scrutinizing the scaffold's design, including its components and connections, to ensure they can handle the anticipated loads without compromise to safety.

5. Regular inspections and maintenance

Once scaffolding acceptance has been achieved, it is essential to schedule regular inspections and ongoing maintenance to ensure continued safety and functionality. This includes periodic assessments of the scaffold's condition, such as checking for corrosion, loose fasteners, or damaged components, to identify any potential risks and promptly address them. Regular maintenance not only prolongs the scaffold's lifespan but also minimizes the chances of accidents or malfunctions during use.

Conclusion

Scaffolding acceptance in the Mold Base industry involves various essential considerations to ensure both the safety and efficiency of workers. Compliance with regulations and standards, assessing structural integrity and stability, ensuring adequate access and platform safety, evaluating load-bearing capacity, and implementing regular inspections and maintenance all contribute to creating a secure working environment. By understanding and expecting these aspects, the Mold Base industry can effectively operate within safe and reliable scaffolding structures.